- Bad connection

- Fault in the ECU

2.4 Record the reading from the meter

5.14V

Is this acceptable or unacceptable reading?

This is a acceptable reading.

2.5 What is the purpose of the reference voltage to the throttle position sensor?

To supply the 5 volts input and to compare the signal wire with 5 volts.

2.6 What could cause problems so that there is not the correct refrence voltage at the throttle position sensor?

If the refrence voltage is incorrect the ECU will be getting the incorrect information about how far the throttle is opened.

3.0 Ground at TPS sensor

3.3 Record the voltage on the meter

0.05V

3.4 What does this voltage tell you about the ECU earth or ground? Why is it important to measure it?

Since there is no voltage drop therefore the ECU grounding is good.

3.5 Discuss what could go wrong so that the ECU earth or ground is not good.

- Broken wires

- Dry joints

- Corruded joints

- Loose wires

- Damaged circuit board.

4 Throttle Position Sensor return/output

4.2 Record the reading from the meter

5.18V

4.3 Open the throttle to about the half open position, ( make sure engine is not running ) and record the reading on the meter

2.288V

4.4 Open the throttle to the full open position, ( make sure engine is not running ) and record the reading on the meter.

4.05V

4.5 It is O.K

4.7 Describe how a TPS sensor works.

It acts like variable resistor to measure the opening angle of the throttle and idle circuit with the throttle butterfly fully closed, the idle cicuit activates and airflows into engine through the auxillery air values and with the throttle at half or full open the signal is sent to the ECU which determines the injection amount accordingly.

4.8 Discuss what type of sensor voltages should go to the ECU as the throttle is opened and closed.

With the throttle closed the voltage will be minimum whereas the throttle fully opened the voltage will be higher but less than 5 volts.

4.9 Describe problems which could occur to prevent the TPS from sending the correct voltage to the ECU.

- tempered with

- loose connectors

- faulty TPS

4.91 Draw a full circuit diagram for the TPS on this vehicle:

5.0 Throttle Position Switches

5.2 Record wire colours and voltages

- Idle wire colour: White / Blue stripe

- Volts at idle: 12.33V

- Volts at part throttle or open throttle : 2.2V

- Wide Open Throttle wire colour: Red / Blue stripe

- Volts at idle or part throttle: 2.3V

- Volts at open throttle: 4.02V

5.4 Why is this output needed for the ECU to properly run the engine? How do these outputs change how the engine runs in the different conditions of idle, part throttle cruise, and wide open throttle power?

The output from the TPS determines the opening angle and amount of air flowing into the engine. The ECU then determines the fuel injection amount with regards to the other input sensors. The wider the throttle opening angle the more air flow more injection amount.

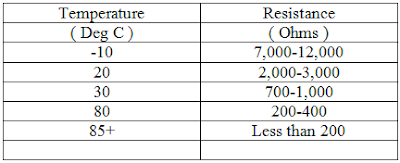

6.0 ECT Engine Coolant Temperature ) Sensor

6.3 Record the reading from the meter

1.8V

6.4 Is the engine cold, between cold and normal temperature ( warming up), or at normal operating temperature ?

Normal operating temperature

6.5 Does the voltage reading above seem right for the temperature of the engine? (yes or no)

Yes

6.6 Let the engine warm up for about two more minutes, and record the voltage of the ECT sensor now:

1.67V

6.7 A warmer engine should usually show a lower voltage. Is the reading above lower than the first reading ? ( yes or no )

Yes

6.8 Describe how an ECT sensor works.

According to the testing as the engine gets warmer the voltage decreases therefore it is negative temperature co-efficient (NTC)

6.9 Describe how the ECT sensor voltage affects the fuel injection output from the ECU.

Higher voltages will determine the engine is cold therefore the fuel injection amount will be more whereas the lower voltages of the ECT the ECU would senses that the engine is at normal operating temperature and hence the injection amount will decrease.

6.10 Describe what could go wrong to create an incorrect voltage for the ECU.

- Shorted out

- Bad connections

- Faulty ECT

6.11 Draw the circuit diagram for the ECT sensor

7.0 Ground Coolant Temperature Sensor

7.1 Record the voltage on the meter

0.04V

7.5 What does this voltage tell you about the ECU earth or ground? Why is it important to measure it?

It tells me that the ECU earth has good grounding therefore it is below the specification and the voltage is 0.04V without any voltage drop.

7.6 Discuss what could go wrong so that the ECU earth or ground is not good.

- Earth wire is loose or broken

- Corrude joint

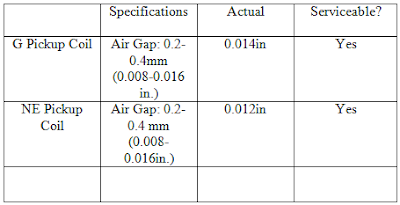

4.0 RPM Sensor or Crank Position Sensor ( CKP )

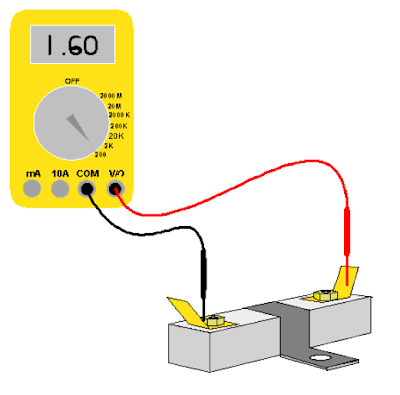

4.5 Record the reading from the meter

1.86V

4.6 Increase engine RPM to about 2500 rpm. Record the reading from the meter.

0.683V

4.7 Return the engine to idle speed. Switch the voltmeter to read DC volts. Record the reading from the meter.

2.5V

4.8 Increase engine RPM toabout 2500 rpm. Record the reading from the meter.

2.401V

4.9 Switch the voltmeter to read Hz. Record the reading from the meter.

2.058KHz

4.10 Increase engine RPM to about 2500 rpm. Record the reading from the meter.

7.49KHz

4.11 Which setting best showed if the RPM sensor was working AC volts, DC volts or Hz

I think the best setting is showed by the Hz

4.12 What type of RPM or Crank sensor is on your engine.

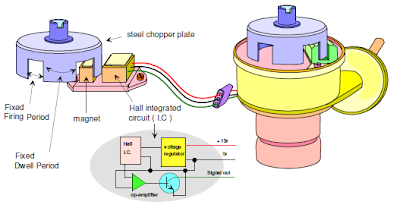

I have inductive sensor on my vehicle's engine4.12 Describe how this type of RPM or Crank sensor works.

4.13 Discuss how using different functions of your meter can help you to accurately measure the sensor output when you don't have an oscilloscope available?

- Faulty sensor

- Broken wire or loose connection

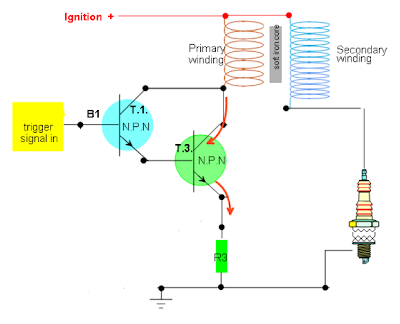

4.15 Draw the circuit diagram of RPM or Crank sensor.

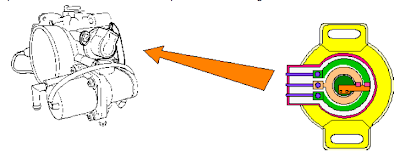

5.0 MAP Sensor

- Faulty MAP sensor

- Broken or loose connection

- Fault in the MAF sensor

- Broken or loose connection.

- fault in the IAT

- Broken or loose connection

9.10 Draw the wiring diagram for IAT sensor

10.0 Camshaft Position Sensor ( CMP )

10.3 Record your meter readings below in the different settings, and discuss which settings show the CMP is good .

DC Volts = 5.15V

AC Volts = 10.5V

Hz = 36.99KHz

% Duty Cycle = 22.1%

10.4 Draw the circuit diagram for Cam Position Sensor